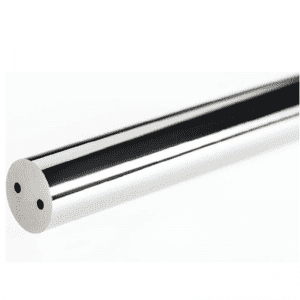

Volfram solida hårdmetallstänger för pinnfräsar och borrar med stabil hög kvalitet

1.Volfram solida hårdmetallstänger pressgjuts genom gjutning eller extrudering.

2. Volframstängerna av solid karbid sintras av en integrerad lågtryckssintringsugn, vilket gör att den totala prestandan är hög.

3. Den grova rundstången av volfram-koboltkarbid eller den yttre diametern på den runda stången kan förfinas och poleras enligt valfri tolerans. De vanliga toleranserna är h5,h6, -0,005, etc. och karbidstavarnas ändfasning kan också bearbetas.

4. Hårdmetallstänger är lämpliga för bearbetning av allmänt stål, gjutjärn, rostfritt stål, värmebeständigt stål, nickelbas och titanlegering. Rekommenderas för generella hårdmetallverktyg som spiralborrar, pinnfräsar, kranar och pistolborrar.

Våra typer av hårdmetallstänger

1.Oslipade långa stavar

| TOL. av Unground Långa stavar | ||

| Storlek (DxL, mm) | Tolerans | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0,30~0,55 | 0,00~+4,00 |

| D[3-12)x310/330 | 0,30~0,60 | 0,00~+4,00 |

| D[12-20)x310/330 | 0,30~0,65 | 0,00~+4,00 |

| D[20-40]x310/330 | 0,30~0,70 | 0,00~+4,00 |

2.Oslipade stavar i längden

| TOL. av oslipade längdskurna stavar | ||

| D/L(mm) | TOL.of D&L i mm | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.